About us

Experience

William Johnston has worked in the quarrying industry for over 15 years. Starting with Cooke Bros Engineering (Newtownards); then working for Sandvik, specialising in Sandvik machines; now working independently to quarries and to Sandvik on static plant.

Problems noticed

- Wear ontop of spider assembly and top shell of sandvik crushers which due to being conical were not easy to plate.

- Ongoing issue –repeat site maintenance visits.

- On different types of aggregate wear was more prevalent.

- On hard stone with high PSV, at around 10 years old these machines had started to wear badly

Stud products

I saw a stud product applied 10 years ago which addressed this issue and have been researching similar products since then. The best available product in this style is made with tungsten carbide and is made by Betek. The extra wear protection from tungsten carbide and the product development and support from Betekgave me encouragement to support the product and apply the shared benefits to our industry.

Advantages of Using TungStuds

- TungStuds are quickly welded on.

- Can also be used on uneven surfaces.

- When TungStuds are worn, simply replace them.

- Resistant to wear, thanks to tungsten carbide.

- Less maintenance work means higher productivity.

- Cost reduction through less downtime.

- Individual TungStuds can also be replaced.

Can be welded in most positions.

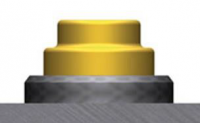

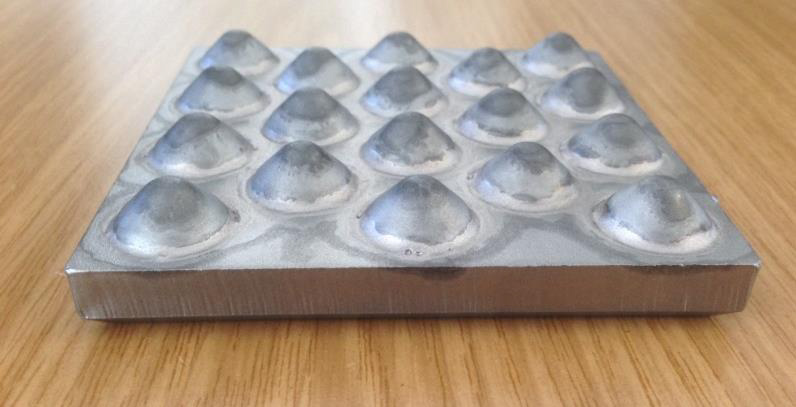

BTS Plates

Weld prepped, heat treated base plates with tungsten caribe tips brazed into the surface. Supplied in 50x50mm, 75x75mm, 100x100mm, 125x125mm, 150x150mm.

Supplied with a 5mm weld prepped. For on site welding using arc or mig.

Less wear thanks to resistant tungsten carbide and the heat-treated baseplate.

| TungStuds type | Current in A | Time in s |

|---|---|---|

| BTS01 | 1200 | 0.6 |

| BTS02 | 1200 | 0.6 |

| BTS20 | 1100 | 0.6 |

| BTS03 | 1350 | 0.7 |

| BTS04 | 1350 | 0.7 |

| BTS05 | 1500 | 0.8 |

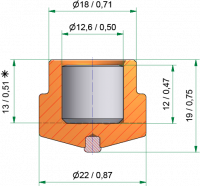

| BTS06 | 1500 | 0.8 |

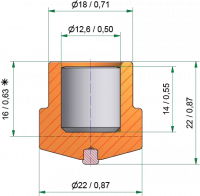

| BTS07 | 1500 | 0.8 |

| BTS08 | 1500 | 0.8 |

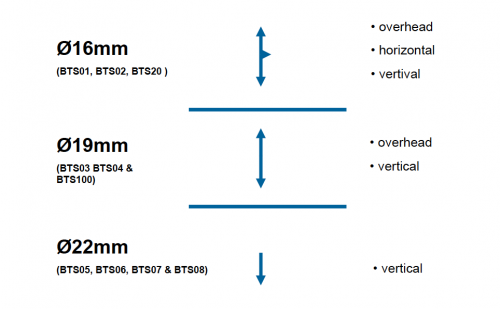

TungStuds Product Range

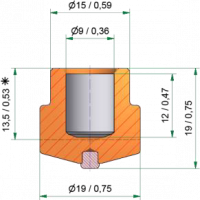

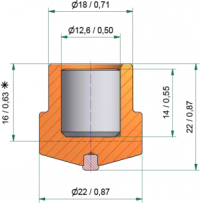

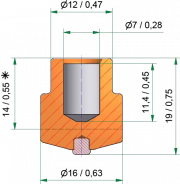

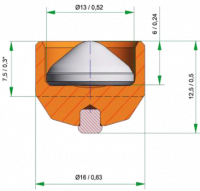

16mm diameter

(bts01,bts02 , bts20)

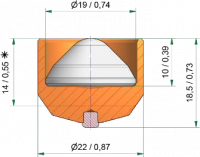

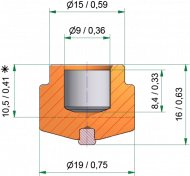

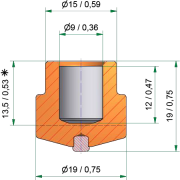

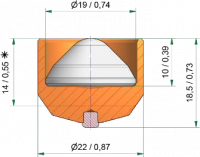

19mm diameter

(bts03, bts04 , bts100)

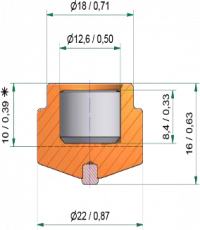

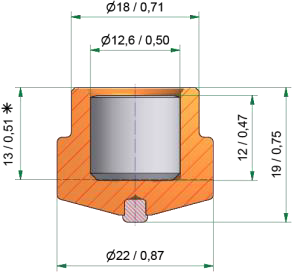

22mm diameter

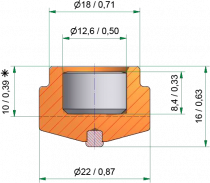

(bts 05 ,06, 07 and 08)

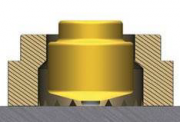

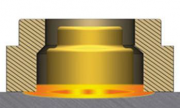

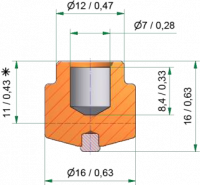

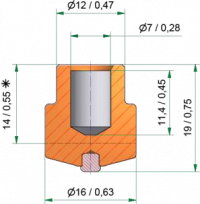

TungStuds 16mm with Tungsten Carbide Core

- Used to form a stone bed.

- Used in impact areas.

- Can be welded in any position.

- Both 16mm diameter studs.

- BTS01 11mm fitted height.

- BTS02 14mm fitted height

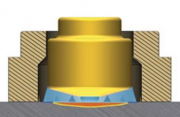

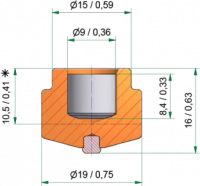

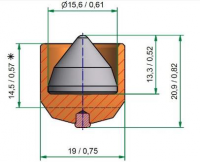

TungStuds 19mm diameter with tungsten carbide core

- Used for impact areas.

- Used to create stone box effect.

- Can be welded overhead.

- BTS03 19mm diameter, 10.5mm fitted height.

- BTS04 19mm diameter, 13.5mm fitted height.

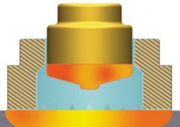

TungStuds 22mm diameter with tungsten carbide core

- 22mm diameter studs with 10mm, 13mm or 16mm fitted height.

- Can only be welded with gun vertical.

- Not for positional welding.

- Quantity in a straight metre 28.

- Quantity in a square metre 700.

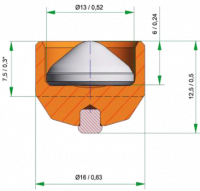

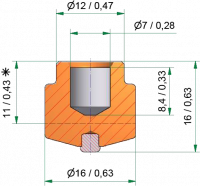

TungStuds with Tungsten Carbide Tip

New Development

Unlike the other studs the Tungsten Carbide is brazed into the stud. The top steel (only required for welding purposes) will wear leaving the Tungsten Carbide tips as a very hard wearing surface. Mainly used for sliding abrasion areas. Not for impact areas The BTS20 (16mm)can be applied in any position.

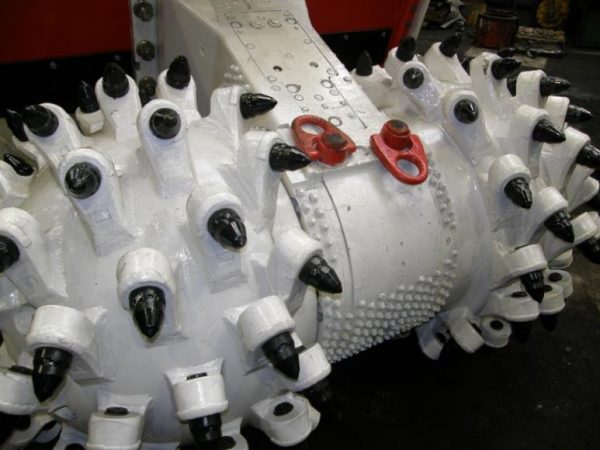

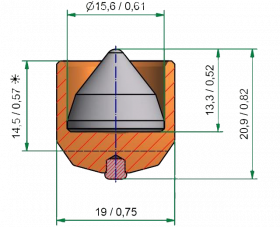

BTS100

- The BTS100 has a tungsten carbide tip (shown in grey).

- Can be welded in most positions.

- Can be welded to a 20mm auger flight.

- Quantity in a straight metre.

TungStuds- Welding Process

Advantages

- TungStuds are quickly welded on.

- Can also be used on uneven surfaces.

- When TungStuds are worn, simply replace them.

- Individual TungStuds can also be replaced.

- Resistant to wear, thanks to tungsten carbide.

- Less maintenance work means higher productivity.

- Cost reduction through less downtime.

- Minimal spare parts expenditure.